With the rapid development of social economy and the continuous improvement of people's material and cultural living standards, the demand for automobiles has increased year by year. Automobile production is highly specialized and basic. In order to comprehensively improve the production efficiency of automobile production lines, electrical automation control systems have been widely used.

However, in production practice, some front-line production personnel do not have a deep understanding of the operation skills and functions of the electrical automation control system, and the research energy allocated to the electrical automation control system is limited, so it is impossible to establish a complete technical system.On the whole, the overall function of the electrical automation control system is relatively weak, and a perfect operation mechanism such as detection and analysis has not been established, so the application value of the electrical automation system cannot be exerted.

Moreover, the intelligent construction of some enterprises is limited. When applying electrical automation systems, it is impossible to integrate modern Internet technology with automobile production systems, resulting in a low level of intelligence in related production technologies.For example, some automobile manufacturing enterprises have not paid enough attention to the Internet + electrical automation control mode, so that the enterprises have not established a complete technical support system in terms of automatic repair and automatic processing of electrical automation control systems, and cannot apply modern big data technology to production. middle.When big data technology is not fully used, production enterprises cannot effectively analyze all kinds of data or information, and thus cannot tap the potential value of information.

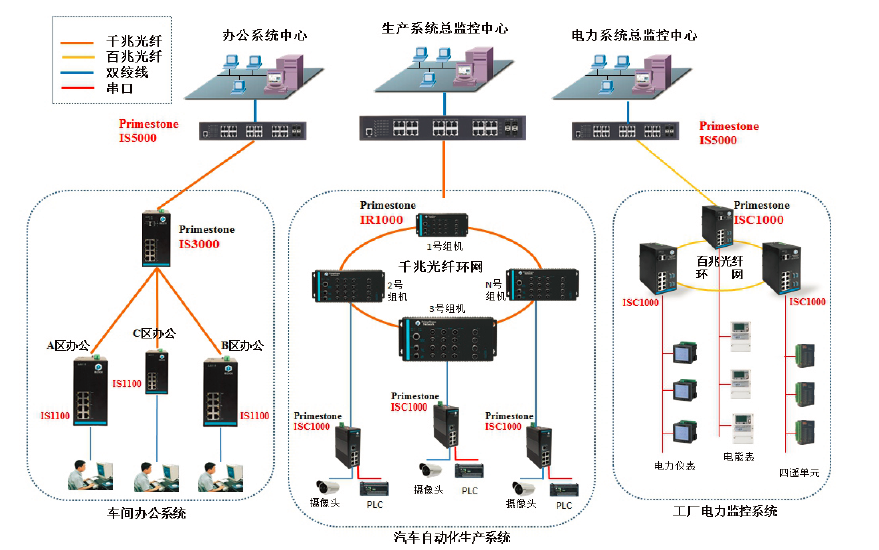

With the update and iteration of production technology, automobile production gradually tends to be automated and intelligent, and develops in the direction of modernization and advancement, which is an inevitable trend of development.In the modern automobile manufacturing industry, more and higher requirements are put forward for automated production. The automated systems include automobile automated production systems, workshop monitoring systems, power monitoring systems, workshop office systems, etc. At the same time, it also puts forward higher requirements for the Industrial Switches that play a key communication role in the automobile automation generation system, which are embodied in the following aspects:

1. Industrial switches must have high reliability to ensure long-term stable operation in automotive manufacturing applications

2. The workshop environment of stamping, welding, painting, and final assembly in the automobile production system requires industrial switches to have high interface protection, anti-vibration and anti-shake

3. Industrial switches must have good resistance to high and low temperature, dust, moisture and corrosion

4. The industrial switch can provide a reliable redundant network, fast recovery and alarm when a fault occurs

5. The industrial switch is resistant to strong electromagnetic interference to ensure stable operation of the equipment in the strong electromagnetic interference environment of the workshop

6. To meet the video surveillance application in the production workshop, the industrial switch can provide sufficient bandwidth and forwarding performance

7. Industrial switches are installed all over the factory, and high security ensures that the equipment will not be illegally invaded and data destroyed

The advantages of Houshi industrial switch solution

1. High reliability, industrial grade 4 standard design, MTBF≥10 years, the production system adopts EN50155 rail dedicated industrial switch, IP67 level protection, rail level anti-vibration and anti-shake

2. The industrial switch adopts the international standard ring network protocol, the self-healing time of EAPS ring network protection is less than 50ms, and the self-healing time of ERPS ring network protection is less than 20ms

3. Industrial switches support high backplane bandwidth and large-capacity cache to ensure fast forwarding of video services

4. Industrial switches support relay alarms to minimize production losses

5. Industrial switches meet EMC/EMI anti-electromagnetic interference and electromagnetic compatibility requirements

6. The industrial switch has passed the harsh environment test of the Taier laboratory and is suitable for low temperature -40°C to high temperature +85°C

7. High security, support 802.1x authentication access, operation user password protection, ACL control strategy

The network topology of the Houshi industrial switch solution:

Contact: sales

Phone: 18688787693

E-mail: sales@hsindustrialswitch.com

Add: Room 608, Building B,GaoXinQi TEC Park,Baoan District, ShenZhen,China