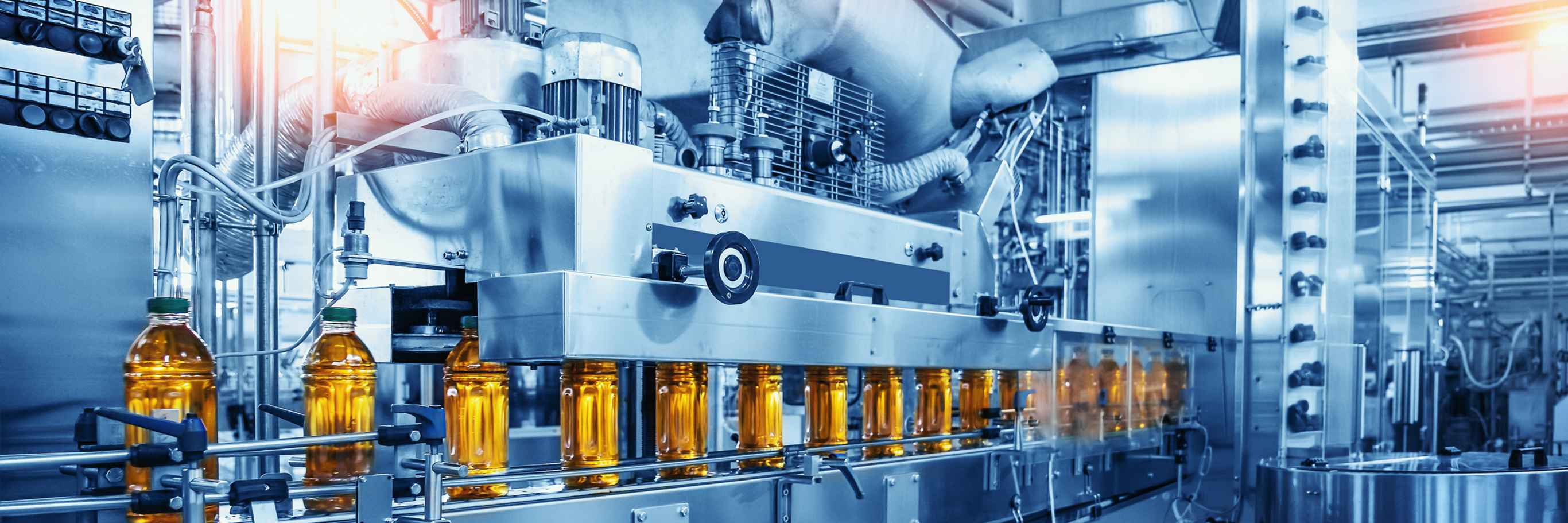

Food processing from production, processing, packaging, storage, to transportation, fully automated production to intelligent management can improve production efficiency and product quality.The higher the degree of automation, the higher the production efficiency and the higher the food safety.Food processing automation systems include food automated production systems, monitoring and environmental monitoring systems, and production office systems.

According to statistics, in the first half of 2021, the operating income of Chinese food industry was 4.37 trillion yuan, an increase of 17.2%, and the profit increased by 17%, showing a stronger development momentum.However, with the rapid development of the Internet, the food industry, as a traditional industry, faces huge impacts and challenges in terms of market demand, development concepts, development models, and industrial patterns.As a product of the deep integration of a new generation of information technology and manufacturing, the Industrial Internet plays an important role in accelerating the transformation and upgrading of traditional industries, and has become a weapon for governments and enterprises to deal with challenges.

Entering the 14th Five-Year Plan period, the state has put forward new requirements for the food industry, requiring that by 2025, the food industry will be significantly improved in scale, intelligence, intensification, and green development, the quality and efficiency of supply will be significantly improved, and the scale of the industry will continue to grow. The structure continued to be optimized, and the digital economy was fast-tracked to accelerate digital transformation.

Food production and processing enterprises have responded to the call of the state and actively explored new Internet models for the food industry, deepened the integration of big data, Internet of Things, artificial intelligence and food processing industry, improved supporting measures for cold chain logistics, and established fully automatic food processing production workshops and central kitchens. , Modern food ecological park, build an Internet platform for the food industry, connect the upstream and downstream of the food industry chain, and solve the pain points, difficulties and blocking points of the food industry.This provides huge market opportunities for industrial switches that play a key communication role in the Industrial Internet, and also puts forward higher requirements for the performance of industrial switches.Specifically in the following aspects:

1. Industrial switch equipment must have high reliability and be able to run stably for a long time in the food processing process

2. Industrial switches should comply with food safety regulations and should not produce toxic and harmful gases

3. Industrial switches must have good resistance to high and low temperature, dust, moisture, oil, acid and alkali corrosion

4. The industrial switch can provide a reliable redundant network and quickly recover when a fault occurs

5. For video surveillance applications, industrial switches must provide sufficient bandwidth and forwarding performance

6. The industrial switch is installed in an open environment, with high security to prevent illegal intrusion and data damage

Advantages of Hoshi industrial switches in food processing

1. The industrial switch has high reliability, industrial grade 4 standard design, MTBF ≥ 10 years, the equipment complies with food safety regulations, and no toxic and harmful gases are generated during operation

2. Adopt international standard ring network protocol, EAPS ring network protection self-healing time is less than 50ms, ERPS ring network protection self-healing time is less than 20ms

3. The wide temperature design of industrial switches is suitable for low temperature -40 ℃ to high temperature +85 ℃, anti-corrosion and dust-proof, anti-salt spray, anti-vibration and anti-shake

4. The industrial switch supports redundant dual power supply wide voltage input, supports anti-reverse connection, overcurrent protection

5. High backplane with widened and large-capacity cache to ensure stable transmission of video data

6. The industrial switch has high security, supports 802.1x authentication access, operation user password protection, ACL control strategy

Contact: sales

Phone: 18688787693

E-mail: sales@hsindustrialswitch.com

Add: Room 608, Building B,GaoXinQi TEC Park,Baoan District, ShenZhen,China