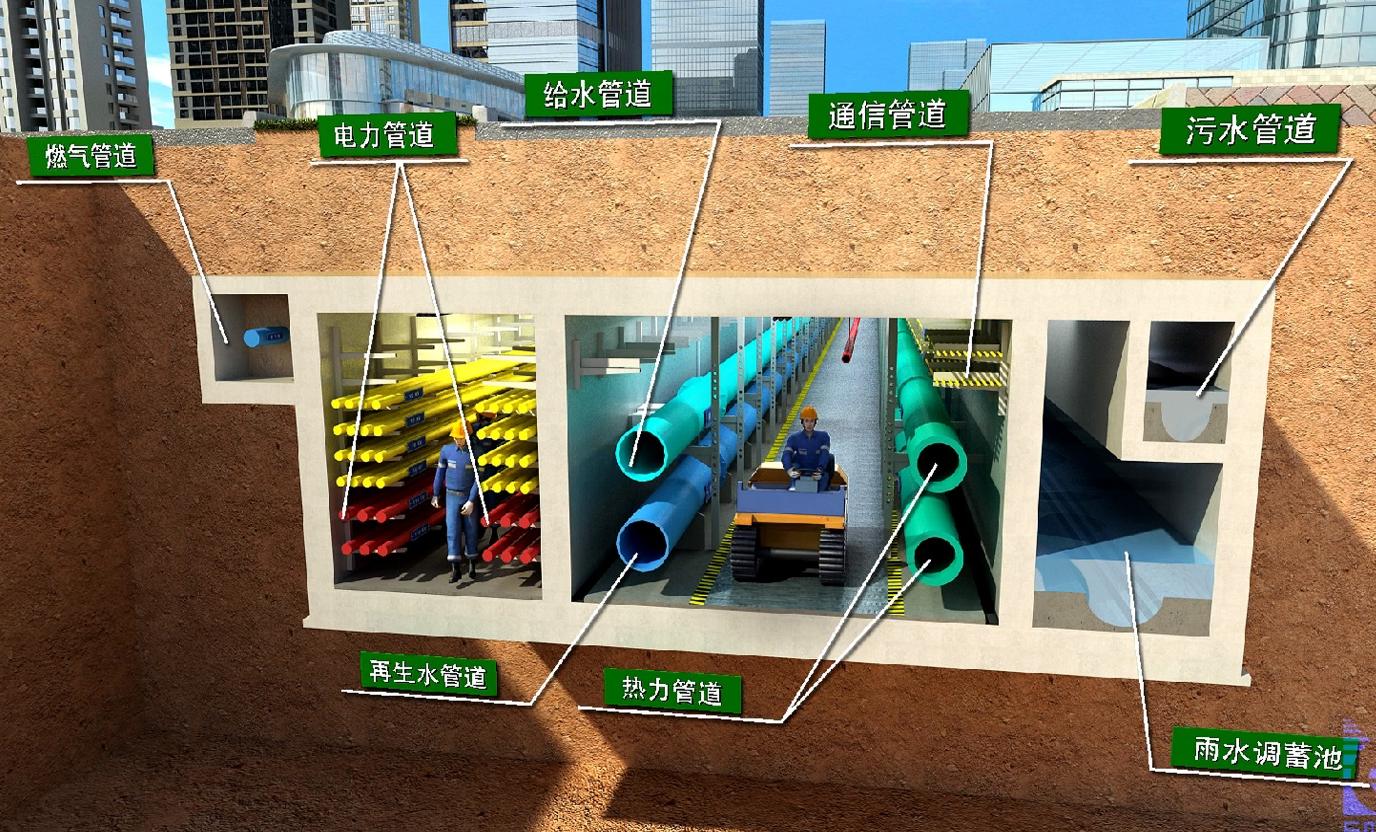

The utility tunnel (underground urban pipeline comprehensive corridor) is the infrastructure that builds a tunnel space under the city to ensure the safe operation of the city, promote overall coordination, save space resources and improve the management level. The integration of power, communication, gas, heat supply, water supply and drainage and other engineering pipelines, the establishment of special manholes, lifting openings and monitoring systems, the implementation of unified planning, unified design, unified construction and management, is an important infrastructure and "lifeline" to ensure urban operation.

The utility tunnel not only integrates the water, gas, electricity and communication pipelines that maintain the urban functions, but also uses a variety of power, lighting, drainage and other equipment for its own functions. No matter the failure of the included pipelines or the failure of its own auxiliary equipment, the function of the cities along the line will be paralyzed. The environment where the urban pipe gallery is located belongs to a relatively closed underground space, and various pipelines in the pipe gallery are complex and have a long laying distance. In this case, data transmission is easy to lose, resulting in many potential safety hazards that cannot be found in time. Therefore, it is particularly important to build a long distance stable and reliable transmission channel. In view of the monitoring needs of the urban utility tunnel, as well as the characteristics of unstable long distance transmission and difficult maintenance in the industrial environment of the pipe gallery, we have launched an Industrial Switch communication solution specifically for the application of the utility tunnel industry, including the video monitoring subsystem and the environment and monitoring subsystem.

System requirements of utility tunnel for industrial switches

The industrial switch adopts reliable optical fiber Ethernet ring network, with long transmission distance and redundant ring network to ensure stable data transmission;

The industrial switch supports the high bandwidth backbone network to ensure the stable transmission of monitoring video and business data;

The industrial switch supports VLAN, ACL, QOS and other data processing to ensure priority transmission of monitoring data;

Industrial grade design standard, supporting wide temperature, meeting the use requirements of harsh working environment on the industrial site;

The industrial switches must have good resistance to high and low temperatures, dust, moisture and corrosion;

The industrial switch is installed in the unattended pipe gallery, and the high security ensures that the equipment will not be damaged by illegal intrusion and data.

Application Solution Design for the utility tunnel of our Industrial Switch

The utility tunnel system is composed of three parts: monitoring center, communication transmission and on-site detection. The monitoring center is the core of the whole system. It contacts, coordinates, controls and manages the work of each subsystem. The communication transmission layer is composed of industrial switches and network transmission equipment. It is responsible for providing access to the data collected by the lower level detection equipment and sending it to the monitoring center, while transmitting the instructions issued by the monitoring center to each site node. The on-site detection consists of webcams, sensors and PLC. PLC is responsible for collecting the detection signals in the pipe gallery and controlling the incoming units of the equipment in the pipe gallery. In order to ensure the effective transmission of data, we use industrial Ethernet to form a gigabit optical fiber ring network by using our full gigabit industrial switch to achieve gigabit network transmission. The gigabit ring network can effectively ensure the stability of data transmission, When a node in the pipe gallery fails, the whole network can quickly converge and recover.

A fire compartment, also known as functional compartment, is set every 200 meters in the utility tunnel. Each compartment is separated by a fire door. Generally, an I/O station monitoring room is set between the two compartments as an access point for the utility tunnel network and other systems, which is responsible for providing access to terminal equipment in the pipe gallery at both ends. A thick stone IS6000 series full gigabit switch is placed in the I/0 station monitoring room to provide access to the central camera Sensors, alarm phones and other equipment provide access. IS6000 series industrial switches at each monitoring station form an optical fiber ring network through optical fibers. To ensure the reliability of the pipe gallery, dual optical fibers can be used to form a network. Optical ports realize bandwidth superposition and link redundancy through link aggregation. IS6000 has its own optical port Bypass function and electrical port POE function. The Bypass function can realize the direct connection of the port in case of switch failure and ensure the smooth link. POE power supply has adjustable capacity of 24VDC/48VDC, which can supply power to AP or IP cameras in the pipe gallery. The IS3000 series rail industrial switch serves as a supplementary access point for the pipe rack to meet different access environment applications.

Core layer: The core switch adopts IS6000 series layer 3 full 10 gigabit switch, high backplane bandwidth, large capacity cache, and multiple security management strategies to meet the communication needs of various systems of the utility tunnel monitoring platform.

Convergence layer: The convergence switch adopts the our layer 3 industrial switch, supports the fast ring network protocol, and forms the convergence protection ring network by cascading the upper optical ports.

Access layer: The front end access industrial switch adopts our security special managed POE industrial switch, which provides 4-way PoE ports, supports the fast ring network protocol, and forms an access protection ring network by cascading the upper optical ports.

Application Solution Features of our industrial switch in utility tunnel industry

All the equipment are industrial grade products, and all the industrial switches used have passed the national grid A certification and IEC61850-3 standard.

Industrial switches are of wide temperature and wide voltage, redundant dual power supply, and the working temperature can reach - 40~85 ℃.

The protection level of industrial switches is IP40 or above.

The industrial switch supports redundant optical fiber ring network, which is simple, stable and reliable.

Private fast ring network technology, with failover time less than 20ms.

The industrial switch has perfect network management functions. In addition to supporting common management methods such as CLI, Telnet, and WEB, the switch also has powerful SNMP management functions. The powerful integrated network management software NIS can detect the health of the whole network in a timely, accurate and comprehensive manner.

We have been focusing on the solution of the Utility Tunnel for many years. Our industrial switch series products are widely used in the video monitoring, environmental monitoring, equipment monitoring and other systems of the comprehensive pipe gallery, winning the trust and favor of consumers!

Contact: sales

Phone: 18688787693

E-mail: sales@hsindustrialswitch.com

Add: Room 608, Building B,GaoXinQi TEC Park,Baoan District, ShenZhen,China