Digitalization, clustering and networking have become the inevitable trend of the application of wireless communication technology in the oil and gas field industry. Safe, reliable, powerful, economical and practical wireless communication systems, especially Industrial Switches, are playing an increasingly important role in the safe production, equipment management and maintenance, product transportation and emergency disposal of petrochemical enterprises. It has become an indispensable part of enterprise production management and system construction.

Oil and gas field companies include company headquarters, oil production plants, gas production plants, data centers, pipeline companies, subordinate exploration companies, research institutes and other branches. Oil and gas field companies cover a long distance, and these branches are often far away from each other. As the carrier of oil and gas field production and office communication business, the basic network directly affects the production and operation efficiency of oil and gas fields. In addition, with the development of video surveillance and video conference services, the demand for bandwidth is increasing day by day, and the original network has gradually failed to meet the demand.

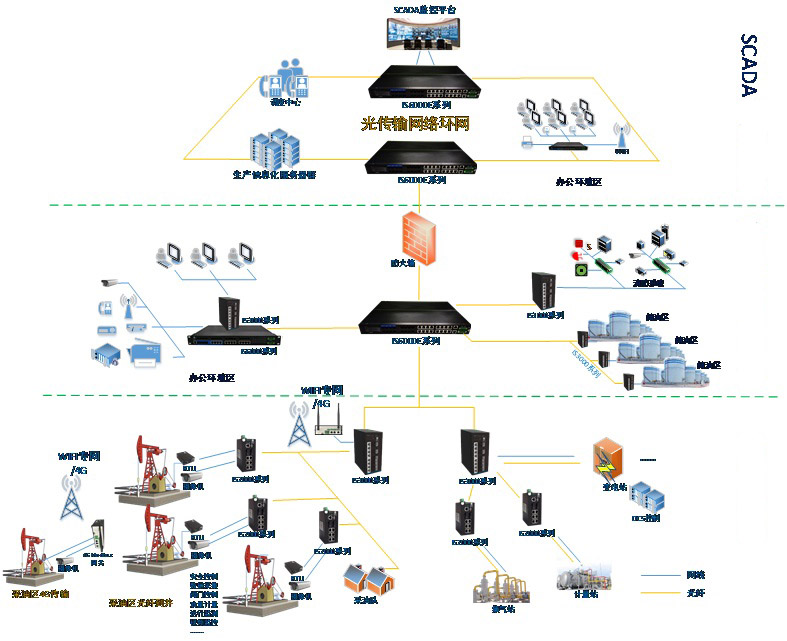

The intelligent digital oil and gas field communication network must build a safe, efficient and reliable automation network through industrial switches to improve oil field production, strengthen production process control and assist production management. Through wired optical fiber transmission network and wireless transmission network, real-time transmission and sharing of production data and equipment status information among oil and gas field well area, metering room, gathering and transmission station, combined station and processing plant can be realized.

System requirements of oil and gas field communication network on industrial switch:

1. The communication network meets the industrial design standards and can achieve safe, reliable and stable operation in harsh environment;

2. High bandwidth backbone network, capable of simultaneously transmitting large traffic IP data such as video, audio and business data;

3. Support redundant self-healing function, and can recover quickly in case of network failure;

4. Secure network to protect monitoring from malicious attacks;

5. It has strong network management capability, supports rapid network fault diagnosis, and ensures stable operation of the system.

The use requirements of industrial switches in various production links of oil and gas fields:

(1) Survey: in the field application environment, the site lacks communication guarantee and the working environment is poor. The industrial switch system is required to have high mobility and set up emergency links to ensure timely cooperation, personnel safety monitoring and positioning.

(2) Mining: in the field application environment, the public network signal is poor or no signal, and the working environment of industrial switch equipment is poor. It is required that the patrol inspection and security of industrial switch equipment shall realize backup link and on-site video collection, and the equipment shall have a certain explosion-proof level.

(3) Transmission: long distance and wide range, GPS positioning, etc. In this scenario, there may be no signal or signal difference in the public network. Therefore, it is necessary to support multiple fixed-time patrol inspections, strong endurance of industrial switch equipment, high mobility requirements, and emergency links and data collection.

(4) Refining: in the fixed environment, the industrial switch equipment is required to have high explosion-proof, multi-level scheduling, data collection requirements, regular fixed-point inspection and other functional characteristics.

We starts from the overall planning of the communication network. On the one hand, we subdivide the communication service categories according to the intelligent management requirements, reasonably deploy different types of networks according to the business requirements, and configure network equipment; On the other hand, it is necessary to reduce the network hierarchy, build a reasonable network topology, improve the reliability and security of the communication network, and realize the vertical relative independence and horizontal data security sharing of various communication services, so as to build a safe, reliable and efficient communication network for the construction of oil and gas fields.

Features of Our industrial switch solution for communication network of oil and gas field:

High reliability: protection grade above IP40, - 40 ~ 85 ℃ working without pressure, redundant power supply, nuclear level I seismic design

High performance: global networking full Gigabit downlink, uplink 10 Gigabit, large bandwidth, data delay < 5us, video transmission without jammin

High stability: real time monitoring of network status, self repair of network loop detection, storm suppression, fault recovery of ring network < 20ms

High safety: nearly 40 kinds of operation status monitoring and abnormal alarm, and the system meets GB / t22239 level 4 protection safety

Network topology diagram of industrial switch solution for communication network of oil and gas field:

Contact: sales

Phone: 18688787693

E-mail: sales@hsindustrialswitch.com

Add: Room 608, Building B,GaoXinQi TEC Park,Baoan District, ShenZhen,China