In the environment supported by national policies, logistics enterprises should actively integrate industrial resources, explore the development mode and realization path of "Internet Logistics" intelligent logistics, and improve logistics through intelligent hardware, Internet of Things, big data and other intelligent technologies and technologies.

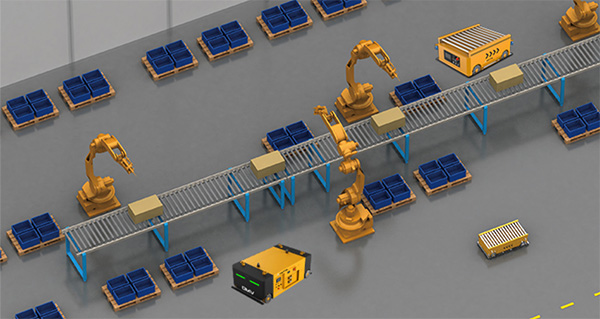

Relying on 5G network communication technology and taking Industrial Switch communication products as the medium, intelligent logistics will build a highly intelligent, self decision-making and integrated intelligent logistics demonstration park through the integration and application of AIIoT, automatic driving, robot and other intelligent logistics technologies and products to promote the integrated interconnection of all people, machines, vehicles and equipment, including the overall scheduling and management of automatic driving, automatic sorting, automatic inspection, human-computer interaction, and build a typical application scenario of 5G technology in intelligent logistics.

The network equipment of automatic sorting system in intelligent logistics mainly includes: Ethernet core switch, central server, monitoring workstation in the center of the group headquarters, Ethernet switch in the convergence layer of the sorting center, Ethernet switch in the access layer, serial port server in the access layer, access layer equipment, sensors, etc.

The stable operation of the automatic sorting equipment control system directly affects the operation status of the sorting equipment of the sorter. In order to ensure the normal operation of the system, some core equipment has been designed with redundancy in the whole system scheme design process. Due to the decentralized control mode, the channel machine product specification can be switched to the vertical and horizontal machine product specification. When a unit fails, it can be handled by manual switch confirmation. Among them, the adoption of single product scale for the passage sorter can not only improve the efficiency but also ensure the normal operation of the system. For data switching between picking channels, the system provides a step oriented dialog box to ensure the security of the system in the switching process.

The system requirements of the automatic sorting system for the industrial switch in intelligent logistics:

1. The sorting center has many conveyor belt lines, many dust, high temperature, and harsh equipment working environment. The industrial switch is required to adapt to various harsh environments, and the industrial protection level needs to be above IP30.

2. The stability of the communication system determines the sortability rate, misclassification rate and equipment operation time of the automatic sorting system. It is the key technology for the automatic sorting system to complete the automatic sorting of express delivery quickly, accurately and efficiently. Therefore, the industrial switch is required to form a redundant ring network so that it can be switched to the backup line in time in case of failure.

3. Due to the large number of motors and mechanical equipment in the sorting center, the interference factors are large. The industrial switch is required to be highly anti-interference and operate normally under many interference factors. The EMC and EMI protection levels are above three.

4. The industrial switch works in the cabinet, not in the core machine room, so the working temperature of the industrial switch is required to be - 30 ℃ - 70 ℃.

5. It supports multiple management modes such as Console, Telnet, Web, and SNMP based network management software, making network management and remote maintenance easier.

6. It supports redundant configuration or redundant input of power supply, anti reverse connection of power supply, and logging of power failure of outfield power supply.

To sum up, the main factors to be considered by the sorting center during the deployment and selection of communication equipment include: industrial Ethernet communication protocol, power supply, port rate, industrial environment certification considerations, installation mode, the impact of the shell on heat dissipation, communication management functions, and the consideration of copper or fiber ports. These are the most basic product selection factors to be understood. If you have higher requirements for the network management of industrial Ethernet, you need to consider the advanced functions of the selected product, such as error alarm, backbone redundancy, ring network redundancy, quality of service (QoS), virtual local area network (VLAN), simple network management protocol (SNMP), port mirroring, and other functions that can be provided in other managed industrial Ethernet switches.

The scheme features of our industrial switches in intelligent logistics automatic sorting system:

1. Good equipment characteristics. Our industrial Ethernet switch is designed with low power consumption and no fan, and supports IP40 industrial protection level and wide temperature operation from - 40 ℃ to 80 ℃.

2. Power redundancy backup. It supports redundant configuration or redundant input of power supply, anti reverse connection of power supply, and logging of power failure of outfield power supply.

3. Strong anti-interference. Our industrial Ethernet switch has passed the industrial level IV electromagnetic compatibility test. It has high protection performance in lightning protection, fast pulse group protection, anti-static and other aspects, and can effectively prevent various interferences in the sorting center;

4. High reliability, instant ring network self-healing ability. Our industrial switch supports the use of technologies such as RSTP, RapidRing and Trunking to improve the security, reliability and stability of the network, and ensure the undisturbed switching of network communication, with the switching time less than 20ms (network self-healing time).

5. Rich functions and high intelligence. Our Industrial Switch has rich management functions, such as Simple Network Management Protocol (SNMP) for remote monitoring and configuration, port mapping for diagnosis, virtual local area network (VLAN) for grouping network equipment, and priority ranking function for ensuring priority messages to pass. Our industrial switch can also limit the abnormal load of switch bandwidth caused by excessive data flow of broadcast packets, multicast packets and unicast packets with wrong destination address, improve the overall efficiency of the system, and maintain the safe and stable operation of the network.

Summary: Our industrial switch adopts large-scale modular, fanless design, wide temperature range, industrial level electromagnetic compatibility and reliability design to meet the networking requirements of the network system of the intelligent logistics sorting center and all the harsh working environments on the site, so as to ensure the efficient and stable operation of the automatic sorting system of the intelligent logistics sorting center.

Contact: sales

Phone: 18688787693

E-mail: sales@hsindustrialswitch.com

Add: Room 608, Building B,GaoXinQi TEC Park,Baoan District, ShenZhen,China