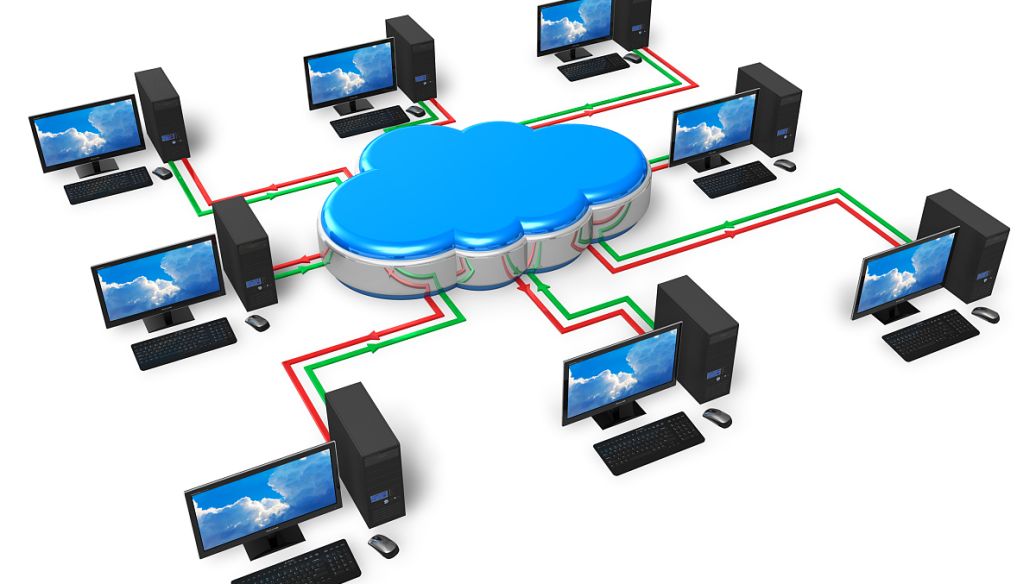

With the continuous improvement of industrial automation level, the number and complexity of industrial equipment are also rapidly increasing. In this context, how to achieve centralized management and monitoring of industrial equipment has become an urgent problem that many enterprises need to solve. As one of the key network devices, industrial Ethernet switches are demonstrating tremendous advantages in industrial equipment management and monitoring due to their excellent performance and functionality.

The advantages of centralized device management

Real time monitoring and fault prediction: Industrial Ethernet switches can capture abnormal situations in a timely manner and perform predictive maintenance by monitoring the operating status of devices in the network in real time. This helps to reduce equipment failure rates and improve production efficiency.

Unified configuration and upgrade: Centralized management allows administrators to configure and upgrade all devices uniformly through a central console. This simplifies the management process, reduces management costs, and ensures that the equipment is in the latest operational state.

Centralized Data Storage and Analysis: Industrial Ethernet switches store device data in a centralized manner, providing enterprises with a better foundation for data analysis. Through in-depth analysis of equipment operation data, enterprises can develop more scientific production plans and management strategies.

Remote maintenance and control: One of the advantages of centralized management is that it enables remote maintenance and control of equipment. Administrators can monitor, maintain, and troubleshoot devices through the network without the need to be physically present, improving work efficiency.

The advantages of industrial Ethernet switches

Industrial Ethernet switches, as the core equipment of industrial networks, can achieve high-speed and real-time data exchange. Its powerful transmission capability ensures fast and reliable communication between devices, providing a solid foundation for centralized management and monitoring.

Firstly, industrial Ethernet switches have the characteristics of high reliability and stability. Industrial equipment often requires long-term stable operation, which has high requirements for the stability of network equipment. The industrial Ethernet switch adopts industrial grade hardware design, which has high anti-interference ability, dust-proof, waterproof, and shockproof characteristics, and can operate well in harsh industrial environments. Its reliability and stability ensure long-term and stable management and monitoring of industrial equipment.

Secondly, industrial Ethernet switches support large-scale industrial equipment connections. In industrial production environments, there is often a need for large-scale equipment access and connection, and traditional network equipment cannot meet this scale requirement. Industrial Ethernet switches have the characteristics of multiple ports, high-speed transmission, and large bandwidth, which can support the connection of large-scale devices. Whether it is industrial robots, PLC controllers, sensors, or monitoring equipment, they can easily be connected to industrial Ethernet switches to achieve centralized management and monitoring of equipment.

Thirdly, industrial Ethernet switches provide rich network management and monitoring functions. Through industrial Ethernet switches, comprehensive centralized management and monitoring of connected industrial equipment can be achieved. Industrial Ethernet switches support functions such as remote management, configuration backup and recovery, device status monitoring, and fault isolation. Administrators can remotely manage devices through the network, configure and manage them, monitor their status in real time, and quickly locate and isolate problems when they occur. This makes the operation of the equipment more efficient and reliable, reducing the cost of equipment maintenance and fault handling.

Fourthly, industrial Ethernet switches provide security and data protection. Security and data protection are crucial in industrial equipment management and monitoring. Industrial Ethernet switches ensure the security of devices and data by supporting various network security protocols and mechanisms. For example, supporting VLAN and ACL functions can achieve network isolation and access control, ensuring the security of device data. At the same time, industrial Ethernet switches also provide data backup and recovery functions, ensuring data integrity and reliability.

Finally, industrial Ethernet switches have scalability and flexibility. The industrial production environment often requires frequent equipment changes and network expansion, and traditional network equipment often cannot meet this demand. Industrial Ethernet switches have scalability, can support fast access to new devices, and can flexibly expand and adjust network structures according to needs. Whether it's increasing the number of devices, changing the topology, or dealing with complex network environments, industrial Ethernet switches can provide flexible solutions.

In summary, industrial Ethernet switches, as a powerful tool for centralized management and monitoring of industrial equipment, play an indispensable role in the field of industrial automation. Its reliability, scalability, rich network management and monitoring functions, as well as security and data protection, provide enterprises with an efficient and reliable solution. While pursuing maximum production efficiency and cost reduction, industrial Ethernet switches help enterprises achieve centralized management and monitoring of industrial equipment, improve production efficiency, and ensure the safety and reliability of industrial production.

Contact: sales

Phone: 18688787693

E-mail: sales@hsindustrialswitch.com

Add: Room 608, Building B,GaoXinQi TEC Park,Baoan District, ShenZhen,China