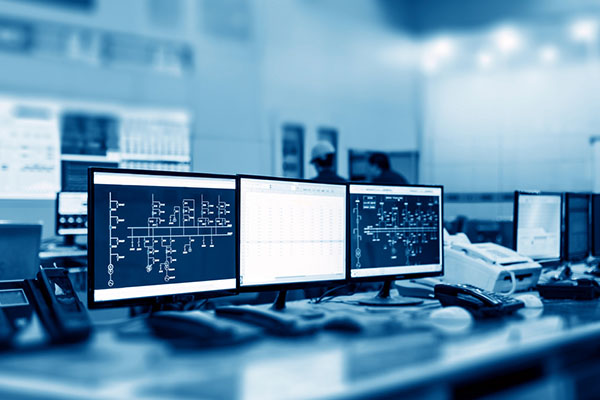

The comprehensive automation control system of the mine is mainly composed of information management system, mine environmental safety monitoring and monitoring system, production equipment automatic control system, and video monitoring system. It can achieve monitoring and control of various production environments and equipment in the entire mine from the central dispatching control room on the ground, playing a crucial role in improving mine production efficiency and safety production. Due to the unique operating environment of coal mine automation control and environmental monitoring systems, there are high requirements for explosion-proof, dustproof, and moisture-proof communication equipment, as well as for the reliability and ability to withstand harsh environments of the communication system.

As an important resource development and production base, the application of comprehensive automation control systems in mines not only improves production efficiency, but also ensures the safety of miners. In this system, Industrial Switches play a crucial role in providing reliable data transmission and network connectivity, ensuring efficient operation and security of the system. This article will focus on the industrial switch application solution of the mine comprehensive automation control system, and provide a detailed introduction to its importance and advantages.

1. Efficient data transmission and network connectivity

1) High speed data transmission: The mine comprehensive automation control system requires real-time monitoring and control of multiple devices, collecting a large amount of data. Industrial switches can quickly and stably transmit data by supporting high-speed data transmission, ensuring the accuracy and timeliness of real-time monitoring and control.

2) Large bandwidth support: There are numerous devices and a large amount of data in the mine comprehensive automation control system. Industrial switches provide high bandwidth support, which can meet the high requirements of the system for data transmission and ensure smooth data transmission and processing.

3) Network connection reliability: Industrial switches adopt reliable network connection technologies, such as redundant links and network loopback detection, to ensure the stability and reliability of network connections. Even in harsh mine environments, the continuity and stability of the system can be guaranteed.

2. Flexible Network Topology and Device Management

1) Elastic network topology: The equipment of the mine comprehensive automation control system is widely distributed, and the flexibility of the network topology structure is crucial. Industrial switches support multiple network topologies, such as star, ring, tree, etc. They can be flexibly laid out according to the actual situation of the mine, optimizing system performance and transmission efficiency.

2) Equipment management and control: Industrial switches provide powerful equipment management and control functions, which can centrally manage and monitor various equipment in the mine comprehensive automation control system. Administrators can achieve centralized management and maintenance of equipment through remote configuration, fault detection, and other functions of industrial switches, improving system availability and stability.

3. Network Security and Data Protection

1) Security access control: In the comprehensive automation control system of mines, security is crucial. Industrial switches support security mechanisms such as VLANs (virtual local area networks) and ACLs (access control lists), which can implement strict access control policies, restrict access and communication between devices, and protect the system from unauthorized access and attacks.

2) Data protection and backup: The data in the mine comprehensive automation control system is crucial for production and management. Industrial switches ensure data security and reliability by providing data protection and backup functions. In the event of system failure or data loss, backup data can be used for recovery and reconstruction to avoid production interruption and data loss.

Industrial switches play a crucial role in the comprehensive automation control system of mines, ensuring the efficient operation and security of the system by providing efficient data transmission, stable network connectivity, flexible network topology, and strong security guarantees. Mine enterprises can improve the efficiency and stability of the mine comprehensive automation control system by adopting suitable industrial switches, and achieve safe and efficient production and operation.

The application of the Houshi industrial switch in the comprehensive automation system of the mine can effectively integrate the production condition information of each production link in the mine under heterogeneous conditions, and can organically integrate the data, voice, and video of each subsystem, providing scheduling personnel with corresponding permissions to monitor, monitor, and control the main links and key equipment of safe production in the entire mine in real time, achieving data collection and necessary control of the entire mine Process control, production scheduling, and decision-making command provide effective means for mine safety production, effective prevention and timely handling of various unexpected accidents and natural disasters.

Contact: sales

Phone: 18688787693

E-mail: sales@hsindustrialswitch.com

Add: Room 608, Building B,GaoXinQi TEC Park,Baoan District, ShenZhen,China