The communication between industrial Ethernet switches and industrial robots is an important component of modern industrial automation production. With the accelerating trend of digitalization and intelligence in the industrial field, stable and efficient communication between industrial Ethernet switches and industrial robots has become increasingly important. This article will revolve around this theme, delving into the importance, application scenarios, technical characteristics, and future development trends of industrial Ethernet switches and industrial robot communication.

The criticality of communication between industrial Ethernet switches and industrial robots:

High speed real-time communication: The operation of industrial robots in manufacturing environments requires fast and real-time data transmission. Industrial Ethernet switches ensure that robots can quickly respond and execute tasks, improving overall production efficiency by providing high-speed and reliable communication channels.

Big data processing and analysis: Industrial robots generate a large amount of data during their work process, including sensor data, motion trajectories, etc. Industrial Ethernet switches serve as the hub for data transmission, quickly transmitting this data to backend servers for the processing and analysis of big data. By analyzing this data, enterprises can optimize production processes, predict maintenance needs, and thereby reduce production costs.

Real time control and collaborative work: Industrial Ethernet switches support real-time control, enabling industrial robots to work in highly collaborative environments. This real-time communication enables multiple robots to collaborate with each other, completing more complex and precise tasks, improving manufacturing flexibility and production efficiency.

The communication between industrial Ethernet switches and industrial robots is of great significance for achieving intelligent manufacturing, improving production efficiency, and reducing costs. As a key equipment in industrial networks, industrial Ethernet switches can achieve data transmission and control of multiple industrial robots simultaneously, ensuring the stable operation of production lines. Industrial robots can communicate with industrial Ethernet switches to quickly obtain production instructions, report production data to the upper system, and achieve more efficient and accurate production operations.

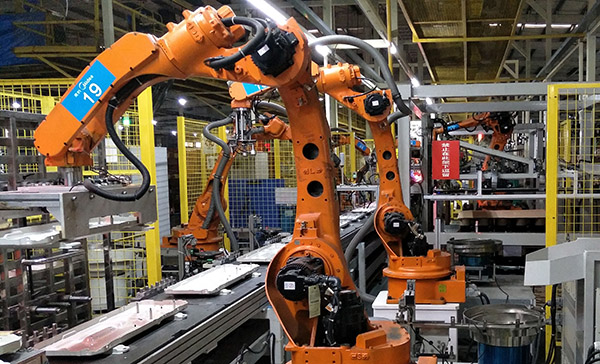

In practical applications, industrial Ethernet switches and industrial robot communication cover many application scenarios. For example, the operation of industrial robots on automated production lines in workshops requires data exchange with other devices such as PLC and MES through industrial Ethernet switches; For example, in intelligent warehousing systems, real-time communication and collaboration between industrial robots and AGV cars need to be carried out through industrial Ethernet switches. These scenarios require high-speed transmission, low latency, and high reliability communication support, and industrial Ethernet switches play a very important role in them.

In terms of technical characteristics, industrial Ethernet switches and industrial robot communication have the following characteristics:

1. High reliability: The industrial Ethernet switch adopts an industrial grade design, which has characteristics such as dust-proof, waterproof, and anti-interference, and can adapt to harsh conditions in industrial environments, ensuring stable and reliable communication.

2. High speed transmission: Industrial Ethernet switches support high-speed transmission at the gigabit and gigabit levels, which can meet the needs of big data transmission and real-time control of industrial robots.

3. Flexible Expansion: Industrial Ethernet switches support modular design and can be flexibly expanded and customized according to actual needs, meeting the application scenarios of different communication network topologies.

4. Rich protocols: Industrial Ethernet switches support various industrial communication protocols, such as Profinet, Modbus TCP, EtherNet/IP, etc., seamlessly connecting with industrial robots from different manufacturers.

In the future, with the continuous deepening of industrial intelligence, industrial Ethernet switches and industrial robot communication will usher in broader development space. Driven by new generation communication technologies such as 5G and the Internet of Things, the communication between industrial Ethernet switches and industrial robots will achieve faster and more stable data transmission; Driven by cutting-edge technologies such as artificial intelligence and big data analysis, the communication between industrial Ethernet switches and industrial robots will achieve more intelligent and efficient production operations.

In summary, the communication between industrial Ethernet switches and industrial robots plays an indispensable role in modern industrial production. Its importance is not only reflected in improving production efficiency and reducing production costs, but also in promoting industrial intelligence and achieving industrial upgrading. In the future, with the continuous innovation and development of technology, industrial Ethernet switches and industrial robot communication will bring more possibilities to industrial production and become an important support in the field of industrial automation.

Contact: sales

Phone: 18688787693

E-mail: sales@hsindustrialswitch.com

Add: Room 608, Building B,GaoXinQi TEC Park,Baoan District, ShenZhen,China